Algae-Produced Bioplastics

Bioplastics are defined as plastics made entirely or partially from biomass or renewable resources, such as food crops and algae, that have the same functions as petroleum-based plastics. As one of the main producers of bioplastics, microalgae can be used to produce bioplastics by several methods, such as direct use of microalgal biomass and blending with other materials.

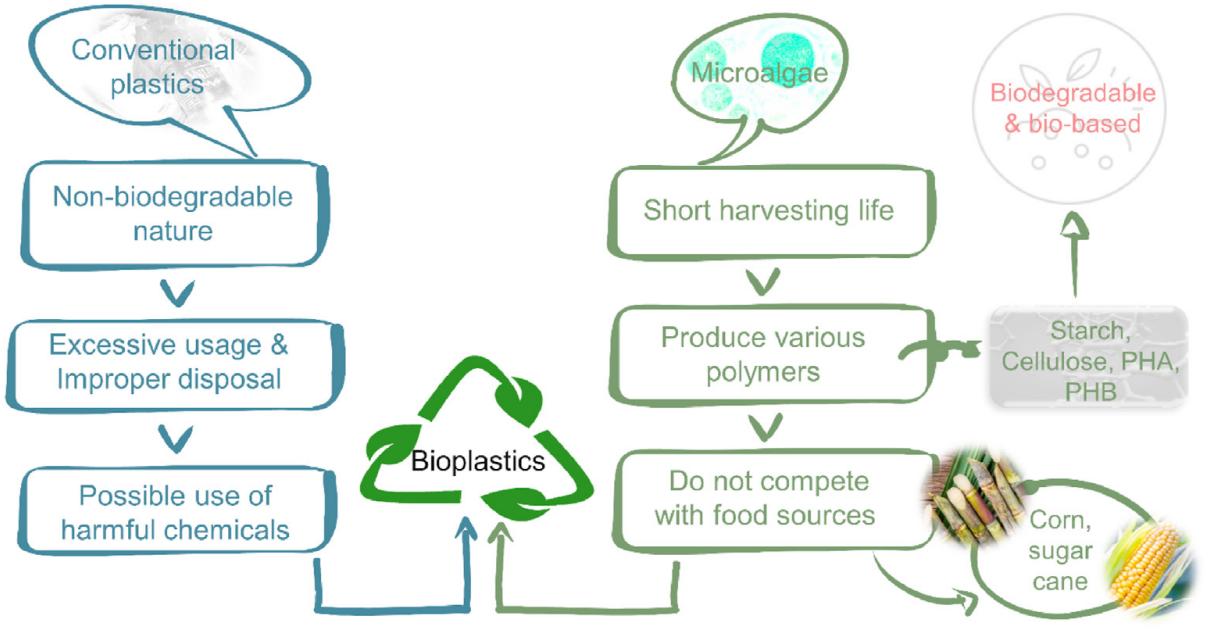

Advantages of Microalgae Production of Bioplastics

There are many sources that can be used to make bioplastics, commonly crops based on agricultural crops such as corn, wheat, soy protein, milk protein, collagen, and gelatin. However, this can lead to competition between crops and humans for land and water resources.

Land and Water Friendly - Algae can be cultivated on non-cultivated land and do not compete with food production for human consumption.

Easy to Cultivate - Algae have short harvesting times and are tolerant to harsh environmental conditions.

Multifunctional - Algae can remediate wastewater and permanently capture and store carbon dioxide while bioplastics are produced.

Fig.1 Advantages of microalgae production of bioplastics. (Chia, W. Y., et al., 2020, Environmental Science and Ecotechnology)

Fig.1 Advantages of microalgae production of bioplastics. (Chia, W. Y., et al., 2020, Environmental Science and Ecotechnology)

PHA from Algae

Algal biomass includes polymers of proteins and carbohydrates that can be used as one of the components of bioplastics. Currently, starch, cellulose, PHA, PHB, PLA, PE, PVC, and protein-based polymers are some examples of compounds from algal biomass used in the development of biodegradable plastics.

Among these polymers, PHA (Polyhydroxyalkanoates) is the most recommended for bioplastic production because it can be biodegraded by enzymatic action.

- Introduction to PHA

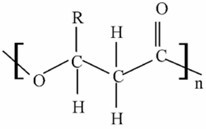

PHAs are polymers of 3 hydroxy acids, named hydroxyalkanoic acid monomers, via an ester bond formed between the carboxylate group of one monomer and the hydroxyl group of an adjoining monomer. The molecular weight of PHAs ranges from 2 to 30 × 105 Da, which seems to be determined by the host organism together with its growth environment. Due to the stereospecificity of the PHA synthase, the structural unit of biological PHA is always in the R(-) conformation, which is necessary for the biodegradability and biocompatibility of PHA. - Two Types of PHA

Based on the number of monomeric carbon atoms, PHAs can be broadly classified into two categories.

Short chain length (scl) polymers with 3-5 carbon atoms as monomers, which are rather fragile and tenacious, with low glass transition temperature and high melting point.

Medium chain length (mcl) polymers, which have monomers of 6-14 carbon atoms, are less crystalline, have lower melting points, and have very low glass transition temperatures compared to scl polymers.

Fig.2 Structure of PHA. (Mal, N., et al., 2022, Chemosphere)

Fig.2 Structure of PHA. (Mal, N., et al., 2022, Chemosphere)

Bioplastic Production by Blending with Other Materials

Microalgal biomass can be blended with other materials, such as petroleum plastics, natural products, or polymers while creating bioplastics to extend their life, improve their performance, and enhance their mechanical properties.

A study used maleic anhydride to modify PE to obtain better interaction. Composites composed of Chlorella sp. and modified polyethylene have greater and more satisfactory tensile strength and thermal plasticity than composites made from unmodified polyethylene. The composites are also able to be easily molded into different shapes by hot press processing. Thus, mixing algae-based plastic products with other materials can improve the physical and chemical properties of bioplastics.

Our Services

With professional devices and teams, Lifeasible is capable to provide high-quality algae isolation and culture services, algae engineering services, algae analysis services, algae genetic screening services, algae-based production services, algae monitoring services, algae treatment services, and algae-based biosensor services for environmental monitoring. Please contact us for more information.

References

- Chia, W. Y., Tang, D. Y. Y., Khoo, K. S., Lup, A. N. K., & Chew, K. W. (2020). Nature's fight against plastic pollution: Algae for plastic biodegradation and bioplastics production. Environmental Science and Ecotechnology, 4, 100065.

- Mal, N., Satpati, G., Raghunathan, S., & Davoodbasha, M. (2022). Current strategies on algae-based biopolymer production and scale-up. Chemosphere, 289, 133178.

Our services are for research use only and not for any clinical use.