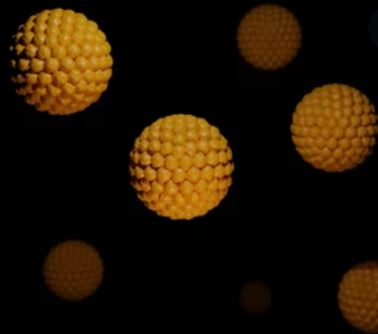

Liposomes are amphiphilic in nature, and both hydrophilic and hydrophobic molecules can be efficiently loaded into liposomes. Liposomes tend to encapsulate water-soluble molecules in the central aqueous phase and lipid-soluble drugs in the region between the bilayer membranes. Also, liposomes have good biocompatibility and biodegradability because the basic structure of biofilm is also a phospholipid bilayer membrane. To improve the stability of liposomes, oligosaccharides, chitosan, alginate, and whey protein can also be added to liposomes as membrane materials. Lifeasible can producing in bulk after the development or modification of liposomes. You can also provide the liposome formulation directly, and we have the professional equipment to provide you with the service of mass production of the product.

The preparation of liposomes is mainly based on the spontaneous arrangement of amphiphilic phospholipids in a solvent. The particle size and bilayer number, particle size, and particle size distribution of the formed liposomes are influenced by the preparation method, lipid type, lipid composition, surfactants, organic solvents, and the ionic strength of the dispersion medium. Common liposome preparation processes include thin film hydration, reverse evaporation, ethanol injection, etc. Laboratory preparation of liposomes with different properties is not difficult. Still, there are only a few techniques for industrial mass preparation, and their use is limited by the process and the molecules to be encapsulated. Therefore, liposome industrial production line equipment generally needs to be customized to the product.

Two main approaches are currently relied upon to control the size of liposomes.

Lifeasible can provide mass production services for liposomes. You can choose your product formulation for mass production, or you can customize the corresponding product formulation for us for production. Our technical team and professional production facilities will provide you with high quality products.

Lifeasible currently has a fully functional analytical department with analytical teams such as a physicochemical analysis group, characterization research group, etc. Each team has experts with extensive experience in the industry and can fully support all quality analysis research related to liposomes from product development, customization, and modification to the commercialization stage.

Our quality control team works closely with our manufacturing, quality assurance, and analytical science teams to provide high quality services to our customers in the areas of liposome development, intermediate process control, and stability studies continuously. We also have a comprehensive analytical method lifecycle management system, including method validation/quality control implementation, continuous method improvement, and method performance monitoring during the process development and commercialization phases.

If you are interested in our services, or if the service you want is not listed, please feel free to contact us, and we will get back to you as soon as possible.