Extrusion is widely used in producing cereals, puffed snacks, bars, and pasta. In addition, extrusion is a key platform for plant-based meat production, including textile soybean isolate proteins and extruded meat analogs. Early extrusion systems relied on simple ingredients and equipment. Still, the demand for high-quality consumer products increased the range of raw materials available, and the complexity of the extrusion process changed dramatically. Extrusion allows using a combination of mechanical and thermal energy to cook a variety of protein sources continuously. The large molecules in plant-based protein components lose their inherent, organized structure and form continuous, viscoelastic agglomerates. As they pass through the extruder barrel and die, they form cross-linked bonding sites and reconstituted expandable structures responsible for the chewy, meaty texture in plant-based meats.

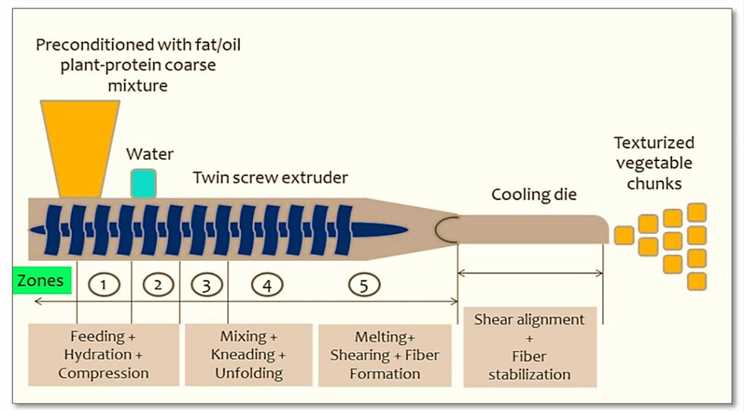

Fig.1. Extrusion technique of making texturized plant-based meat analogue. (Singh M, et al., 2021)

Fig.1. Extrusion technique of making texturized plant-based meat analogue. (Singh M, et al., 2021)

As more and more people continue to adopt vegan and vegetarian lifestyles, there is a growing need to understand and expand plant-based meat processing technologies. Lifeasible is committed to processing plant-based meats using plant-based protein extrusion technology, which is at the heart of plant-based meat production, allowing new ingredients to be blended and cooked in seconds. Over the past few years, Lifeasible has been approached by many companies regarding plant-based protein extrusion, hoping to take advantage of the growing trend to market meat-free alternatives to consumers.

Whether you are an established manufacturer with a history of large-scale food processing or a startup developing a new formulation, we will help you develop the right plant-based protein extrusion process to move from test kitchens to commercial production and cost while managing quality and safety. To meet consumer demand for plant-based meat texture, nutrition, and quality, Lifeasible offers customized solutions for the extrusion-based production of texturized proteins.

Raw materials are typically the most important and expensive part of the texturization process. We typically select materials that allow for successful extrusion processing characteristics, including protein level, protein quality, oil level, fiber level, carbohydrate level, and particle size. We typically select soy flour, wheat gluten, and pea protein as raw materials for extrusion.

We also optimize the extrusion process to preserve the organoleptic flavor of plant-based meats by controlling the reaction temperature, residence time in the barrel, pH, and water activity of the system, etc.

The way each specific material reacts in the plant-based protein extrusion process requires us to be very innovative during the R&D phase to achieve each customer's individual goals. With an in-house laboratory equipped with extrusion machinery, Lifeasible has conducted countless tests on various plant-based proteins and meat substitutes. We are ready to explore the value of extrusion technology to meet the growing demand for new, higher quality, and better tasting plant-based meats. Feel free to contact us for more information.

Reference