Microalgae haveunique growth yields, so using microalgae to produce bioplastics offers an excellent opportunity to increase the sustainability of plastic use. Microalgae, as a potential source for the production of bioplastics, can be used either directly as biomass or as a feedstock for secondary processing. Here, Lifeasible offers specialized solutions for the bioplastics of microalgae.

Plastics have become one of the most essential requirements of modern life. Continued reliance on petroleum-based, non-biodegradable plastics has led to increased global environmental damage and rapid depletion of fossil fuels. Biobased plastics are becoming increasingly popular as marketed alternatives to fossil-based plastics, and they have properties very similar to petroleum-based plastics. Plant-based raw materials, natural polymers, and other small molecules are available for bioplastic production. However, bioplastics derived from crops compete with the food supply. Therefore, microalgae are a potentially better source of biomass for bioplastics production due to their unique advantages.

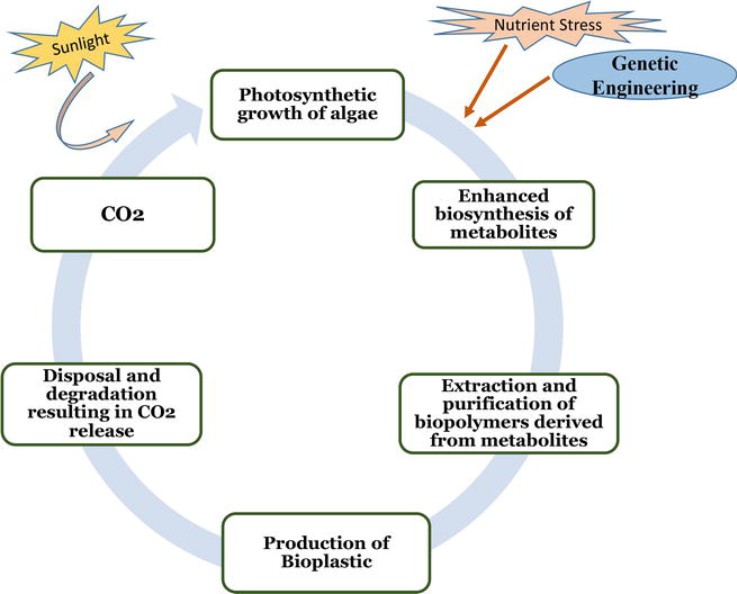

Fig 1. Role of algal bioplastics leading to a circular and green bioeconomy. (Sreenikethanam A, et al., 2021)

Fig 1. Role of algal bioplastics leading to a circular and green bioeconomy. (Sreenikethanam A, et al., 2021)

The production of bioplastics from microalgae represents a new opportunity for exploration and further improvement. We chose microalgae for bioplastic production because it does not compete with food sources, can grow on waste resources, and can achieve high lipid accumulation. In addition, using microalgae to produce bioplastics can be more sustainable and contribute to the circular and bio-economy. Our scientists are exploring a variety of strategies for converting microalgae to bioplastics, including:

Microalgae produce high biomass and metabolites that can be processed into many value-added products. We can achieve direct molding of algal metabolites and algal biomass into bioplastic beads or sheets.

We blend microalgae biomass with petroleum plastics to extend the life of microalgae plastics and provide value-added mechanical properties.

We offer a biorefinery approach to microalgae bioproduct production that reduces the overall cost of the system, allowing microalgae-based bioplastics to be produced at a low cost.

We sequence various microalgae strains and try to incorporate them into different products that may be produced. We offer the implantation of the polyhydroxy butyrate (PHB) pathway into microalgae strains.

We offer mechanical testing, thermal-based analytical methods, SEM, and FT-IR to test microalgal bioplastics to determine properties and study their structural and molecular properties.

As an innovator in microalgae research, Lifeassible offers comprehensive solutions for the design of microalgae-based bioplastics. We have successfully developed a wide range of microalgae bioplastics, including but not limited to the following:

At Lifeasible, we can can quickly design greener and safer microalgae-based bioplastics. We are your trusted partner in all aspects of microalgae research. If you are interested in our solutions, please do not hesitate to contact us.

Reference