Synthetic composite nanomaterials can be prepared by functionalized modification of bacterial cellulose (BC) with carbon nanomaterials. Combined with the physical and chemical methods for the solid loading of bioenzymes, we can design and develop self-powered biosensors based on enzymatic biofuel cells. Integrating energy supply and detection analysis of such biosensors provides the technical and theoretical support for developing novel and highly sensitive membrane sensors. Lifeasible has very professional technology and equipment in bioenergy based and can customize high-quality product solutions for customers.

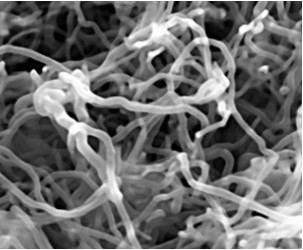

Bacterial cellulose is a natural nanostructured polymeric material with biodegradability produced mainly by bacteria, of which Bacillus cereus is the most capable microorganism for cellulose synthesis. Bacterial cellulose has a ribbon-like shape with a width of roughly 0.01-0.10 μm, which is 2-3 orders of magnitude smaller than the diameter of plant cellulose (typically 10 μm), and fiber lengths ranging from a few hundred nanometers to micron level, with the fibers crossing each other to form a slender mesh structure. Carbon nanomaterials are zero- or multi-dimensional nanomaterials with particle sizes between 1 and 100 nm, such as graphene, carbon nanotubes, diamond, diamond-like, fullerene, and fluorescent carbon nanomaterials or carbon dots, all of which exhibit excellent properties. The combination of the two has good applications for the battery field.

Lifeasible offers product development services for carbon nanotube-modified bacterial cellulose and material characterization testing to provide you with a full range of solutions for your products.

Combining bacterial cellulose with carbon nanotubes can impart excellent electrical conductivity, which can be applied to constructing enzymatic biofuel cells. The composites have ordered nanopore structure, large surface area, and excellent electrical properties, which not only facilitate the adsorption of organic molecules but also facilitate the immobilization of enzymes and promote the direct electron transfer between the electrode surface and the enzyme active center.

1. Scanning electron microscopy (SEM) analysis

SEM is used to characterize the surface morphology of the composites and their structures. The sample surface needs to be sprayed with a thin conductive layer of gold nanoparticles and then tested.

2. Infrared spectroscopy characterization

Infrared spectroscopy (FT-IR, ATR) is used to analyze the samples.

3. Thermogravimetric (TGA) analysis

TGA is used to thermodynamically analyze the fabricated samples to study the decomposition process and rate characteristics at each stage.

4. Electrochemical properties testing

A three-electrode system was used to study the direct electrochemical behavior of the working electrode using cyclic voltammetry (CV).

5. Cell sensitivity and stability testing

Throughout the electrochemical experiments, to study the effect of time on the output voltage of the system, the relative output voltages of different days were calculated by collecting the output voltages of different days and plotting the curves.

6. Power density testing of biofuel cells

To test the power density of the self-propelled sensor, a linear, cyclic voltammetric curve (LSV) was used to study it.

The above is the solution for modifying bacterial cellulose by carbon nanomaterials; if you want to modify the product with other materials, you are also welcome to contact us at any time. We will customize your solution and products for you.