A large number of hydroxyl functional groups on the surface of bacterial cellulose is conducive to improving the doping efficiency after the addition of dopants, and it is also convenient to modify the bacterial cellulose itself to improve its material properties, such as cellulose reaction or grafting required functional groups, to achieve the required particular purpose. Lifeasible provides customers with product development solutions based on the technology and experience of bacterial cellulose. The goal is to help various enterprises accelerate product research and development and provide the application of bacterial cellulose in the energy field.

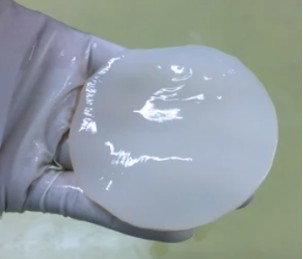

Bacterial cellulose is a general term for cellulose synthesized by certain microorganisms of Acetobacterium, Soil bacillus, Rhizobium, and Diaphylococcus under different conditions. Bacterial cellulose is a porous mesh nanoscale biopolymer synthesized by microbial fermentation. It is named bacterial cellulose because bacteria synthesize it. It consists of distinctive filamentous fibers that are 0.01 to 0.10 μm in diameter, two to three orders of magnitude smaller than plant cellulose (10 μm). The atomic percentage of carbon elements in bacterial cellulose is higher, up to more than 60 percent. The high carbon content makes the activated carbon material produced as a raw material have excellent electrical properties. At the same time, it can make use of its highly netted and refined fiber structure to make holes to obtain active carbon materials with larger specific surface area to increase its specific capacitance and other electrochemical properties.

Lifeasible can provide product development of bacterial cellulose, including carbon nanomaterial modification of materials, to provide customers with the most professional solutions.

Bacterial cellulose has excellent performance and a wide range of applications with high commercial value, and can be modified and modified by various ways to broaden its application field.

The functional modification of bacterial cellulose with carbon nanomaterials can be used to prepare composite nanomaterials. Combining the physical and chemical methods of enzyme solid loading, we can design and develop self-powered biosensors based on enzyme biofuel cells.

In addition to the above product development solutions, we also provide materials characterization testing.

Scanning electron microscope analysis (SEM)

Transmission electron microscopy (TEM) analysis

Infrared spectral analysis (FTIR)

X-ray diffraction analysis (XRD)

Specific surface and porosity Test (BET)

Characterization of heavy metal ion adsorption test

The electrochemical test includes cyclic voltammetry (CV) curve analysis, constant current charge-discharge analysis, and impedance spectrum measurement. The capacitance performance and capacity of the electrode can be investigated, and the internal resistance of the capacitor can be analyzed. The same material under different conditions or materials under the same conditions can be tested through comparative analysis of capacitance performance and optimize the best electrode material preparation method.

By molecular breeding, strains with glucose as raw material can be screened to produce high-yield bacterial cellulose. By improving the fermentation conditions, the yield of bacterial cellulose can be increased significantly, and the production cost and energy consumption can be reduced.

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Get Latest Lifeasible News and Updates Directly to Your Inbox