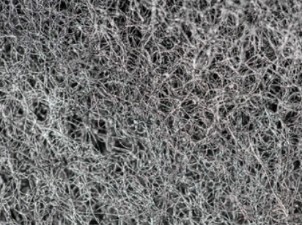

Cellulose nanofibers (CNFs) are cellulose fibers less than 100 nm in diameter and greater than 300 nm in length prepared by physical, chemical, or biological methods. CNFs are composed mainly of plant cell walls and provide strength, toughness, and stiffness to plant tissue structures. CNFs can be extracted from cellulosic bioresources using appropriate mechanical, biological, and chemical or a combination of methods. After an inverse process (top-down deconstruction), cellulose precursors can be separated from the cell wall, and after further nano fibrillation, CNFs with properties such as nano-size, high specific surface area, low density, and chirality are obtained. CNFs are degradable, renewable, have CNFs have excellent properties such as degradable, renewable, high strength, and high Young's modulus, and show good prospects for application in biomedical, high-performance composites, paper making, food packaging, etc.

CNF modification is a simple, inexpensive, and environmentally friendly method to modify CNF by adsorption, chemical grafting, or polymer grafting.

1. Adsorption modification

Adsorption modification CNF can be divided into charged polymer and uncharged polymer adsorption, the uncharged polymer can be combined with cellulose through van der Waals forces, hydrogen bonding, and other effects, and charged polymer can be combined with cellulose through ionic interactions.

2. Non-polymeric grafting modification

CNF with special functions can be prepared by chemical grafting, which means grafting on the hydroxyl group or other functional groups of CNFs to give CNF special functions.

CNF modification can improve the application scope of CNF.

3. Polymer grafting modification

Polymer grafting is the grafting of a polymer onto the CNF surface. A common grafting strategy is to mix CNF with monomer and initiator and then initiate polymerization on the CNF surface.

As a global leader in the development of nanofiber materials, Lifeasible offers strong material development capabilities to provide custom solutions for nanofibers. The following are different types of product modification solutions.

High aspect ratio, tunable surface functionality, low density, and colloidal stability make CNF a promising candidate for hybrid nanostructures. The following are available for development by our research team.

1) Electrostatic binding of cationic nanoparticles to anionic CNF, anionic nanoparticles to surface-modified cationic CNF.

2) Covalent linkage of surface-functionalized nanoparticles.

3) Direct synthesis of nanoparticles on CNF surfaces.

Acetylation improves the thermal degradability of CNF.

Higher surface roughness after modification may help increase hydrophobicity.

Adding a coupling agent changes the hydrophilicity to the hydrophobicity of CNF.

In addition to the above modification development services, we can provide many types of product development to better expand the application of cellulose nanofibers. Lifeasible also can help customers design the right project solution and optimize their products. If you are looking for solutions related to cellulose nanofibers, please feel free to contact us for more information.

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Get Latest Lifeasible News and Updates Directly to Your Inbox