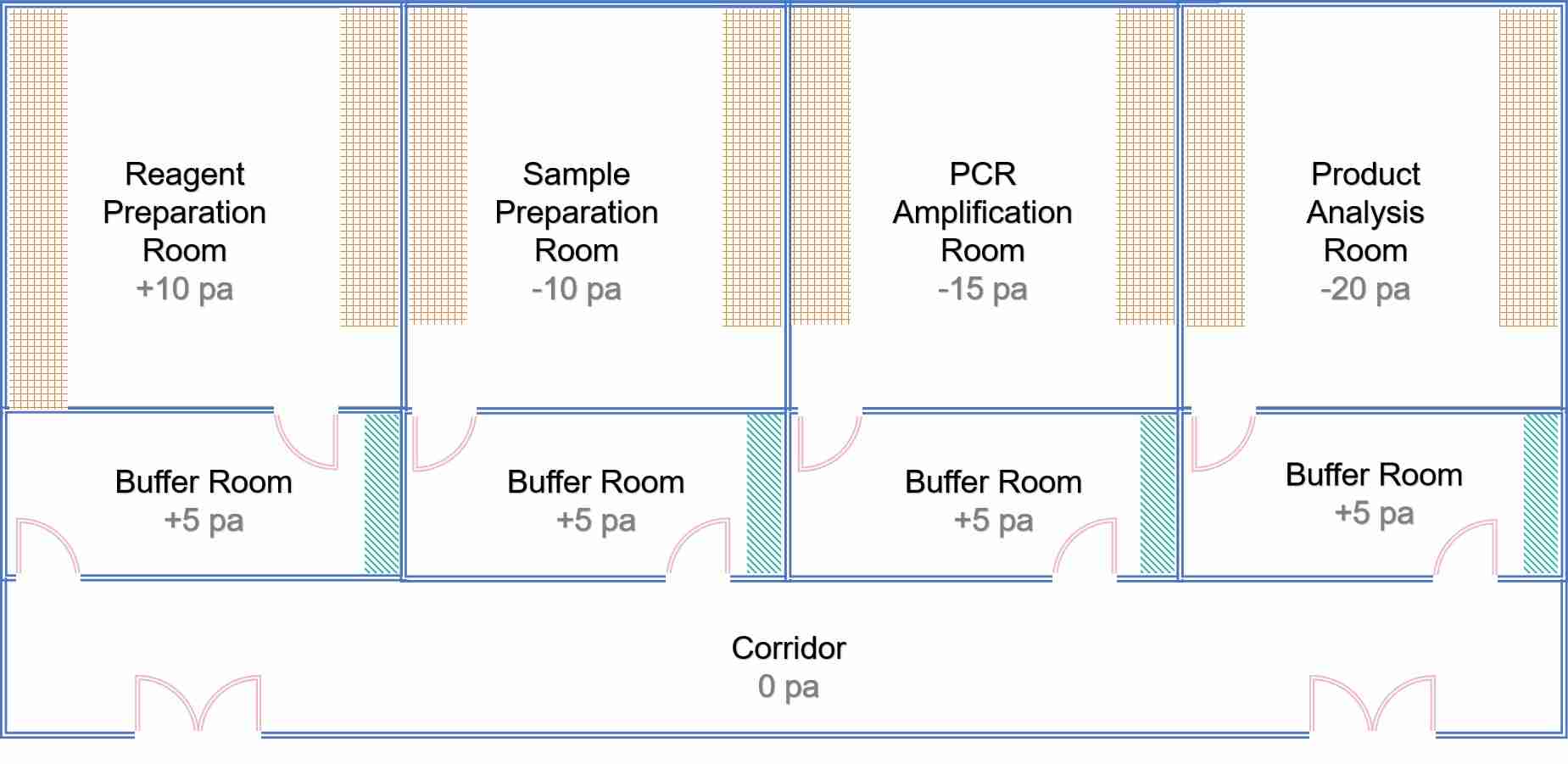

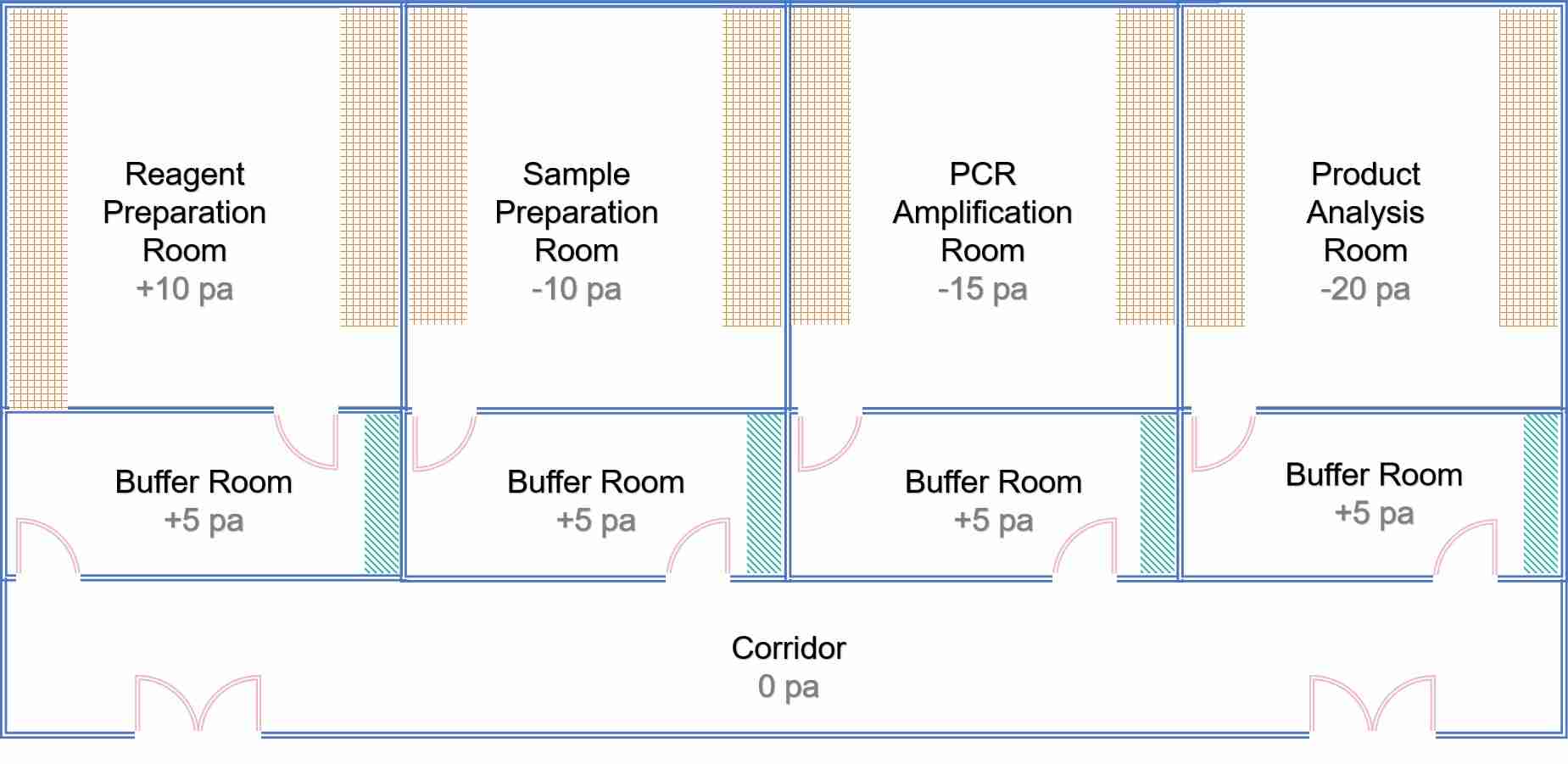

The PCR laboratory is, in principle, divided into four separate work areas, from the pre-amplification area to the post-amplification area, and should be strictly separated. The flow of the experimental process must not be reversed. Lifeasible will set up buffer rooms in each working area according to this basic principle when providing the construction plan, and it is advisable to install interlocking devices between the working rooms and the buffer rooms. For the different functions of the nucleic acid testing workspace, we also advocate that the workspace be set up as separate and distinctly labeled studios, with no direct access between the zones. If you need a layout closely connected between the zones, we can add the design of the item transfer window. We will strictly enforce positive and negative pressure in each area, with independently controllable, fully fed, and exhausted airflow. UV lights should be installed at the top of each working area. We will also consider the temperature control needs of the areas with more equipment.

Design parameter requirements and equipment introduction

- The reagent preparation area (positive pressure) is mainly for preparing amplification reagents and preserving dispensing kits. The main equipment is balance, refrigerator, centrifuge, pipette, and UV lamp.

- The sample preparation area (negative pressure) is mainly for mixing and test sample preparation. The main equipment is a refrigerator, biological safety cabinet (BSC), centrifuge, pipette, oscillator, thermostatic water bath, upper and lower water equipment, waste container, and UV lamp. Depending on the nature and requirements of your sample preparation, we can determine whether to use a BSC or a clean bench. For example, CDC, clinical medical laboratories generally use BSC.

- The amplification area (negative pressure) is the preparation of the PCR amplification reaction system and the addition of the template and nucleic acid amplification. The addition of samples should be carried out in the BSC (or clean bench), the clean bench airflow direction is appropriate to choose the vertical type. Nucleic acid amplification equipment includes a refrigerator, BSC, centrifuge spiker, waste container, and UV lamp.

- Amplification product analysis area (negative pressure) determines amplification products. The main instruments and equipment used are a microplate reader, well washer, pipette, and water bath.

Figure 1. The layout of the PCR laboratory.

Figure 1. The layout of the PCR laboratory.

Common problems in PCR laboratories

- Not according to the design standards on the requirements of the unidirectional process flow, human flow, logistics, and airflow. Not using the full delivery and exhaust of independent airflow organization form is prone to cause cross-contamination and easily produce false positive results.

- The structure part of the sealing is not enough, wall and floor materials, and poor corrosion resistance will impact the use of environmental stability in the process.

- The heat generated by the equipment is not taken into account.

- The buffer room doors are not equipped with interlocking devices, resulting in simultaneous opening.

Advantages

- We have a mature self-use experience and an effective combination of standard procedures, more practical.

- Professional design, provide full-platform building services.

- High recognition in the industry, allowing the establishment of a multi-channel exchange center.

- Timely response to after-sales service and the commitment to extend the warranty period.

- Internet of things (IoT) remote monitoring and integrated control can be realized.

Please feel free to contact us to submit your requirements.

For research or industrial raw materials, not for personal medical use!

Figure 1. The layout of the PCR laboratory.

Figure 1. The layout of the PCR laboratory.