The condensate-free tissue culture laboratory is mainly used for plant tissue culture. Lifeasible's design process takes into full consideration the crop's tissue culture environment, i.e., light intensity, photoperiod, light temperature, dark temperature, humidity, cleanliness, air circulation, and routine maintenance. Different crops have different environmental requirements, and the biggest hidden danger is material contamination and proliferation. Therefore, we adopt the design concept standard for each group culture room to adopt independent fresh air exhaust, temperature, and humidity equipment with a reserve, with our precise control system and cross-flow group culture box, to achieve energy-saving and efficient condensate-free tissue culture.

Design parameter requirements and equipment introduction

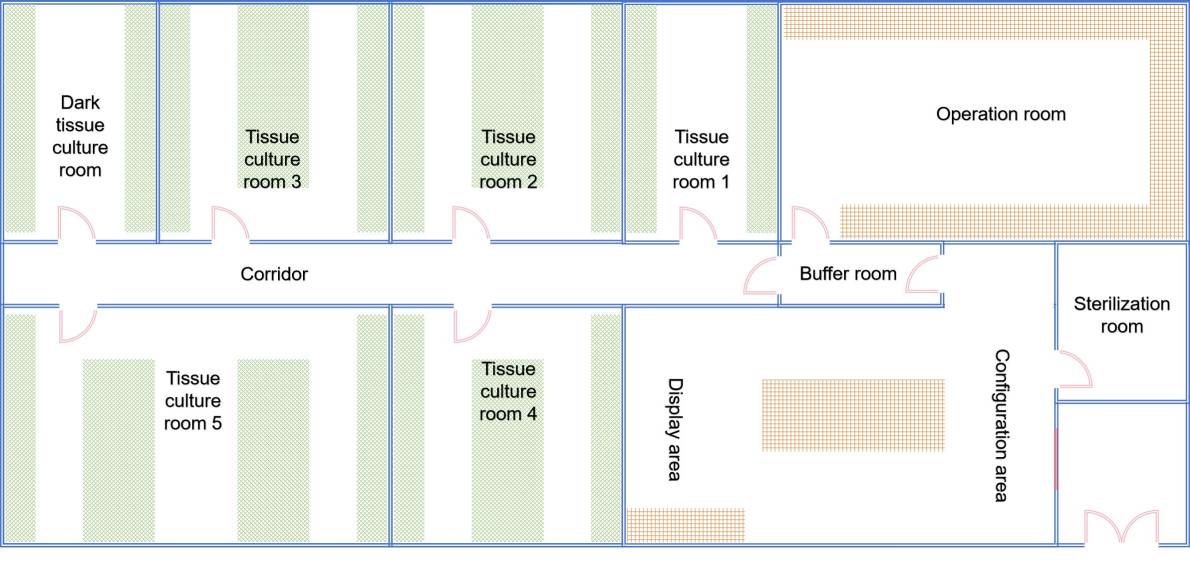

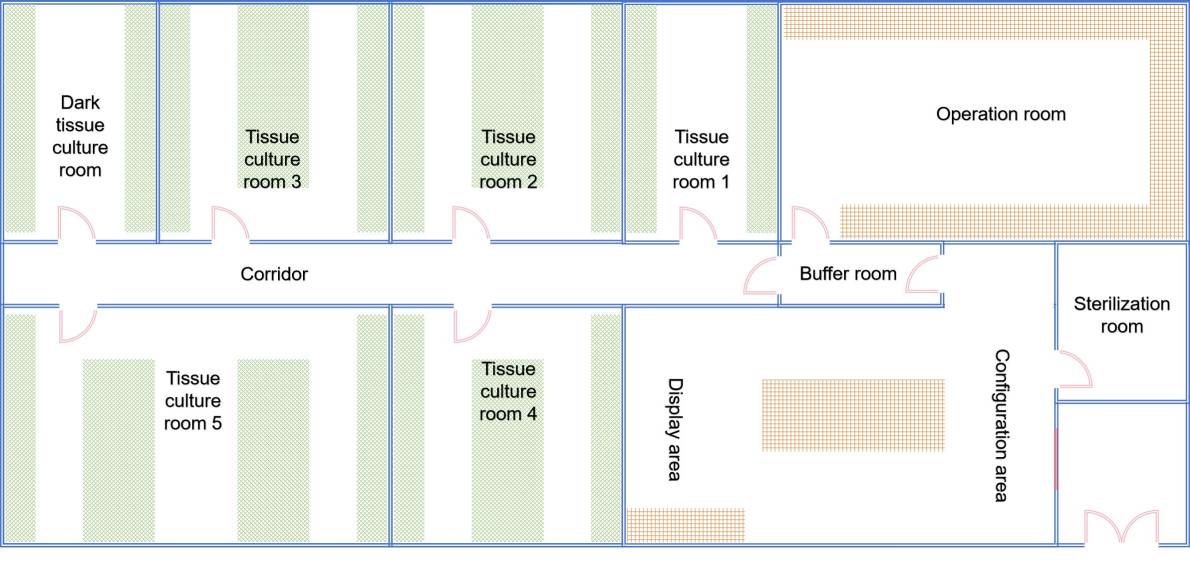

- The cleaning and configuration area is mainly for preparing culture medium, and cleaning of petri dishes and configuration containers. The main pieces of equipment are a balance, refrigerator, physical and chemical test bench, consumables/medicine storage cabinet, and so on.

- The sterilization area is mainly for high-temperature sterilization of culture medium and culture bottles. The main pieces of equipment are an autoclave, transfer window, and so on. Attention should be paid to independent exhaust, temperature control, high-temperature water and gas treatment of autoclaves, etc.

- A buffer zone is a human flow channel from the outside into the operating room. Buffer zone doors should be installed with interlocking devices and a negative pressure environment to ensure that the cleanliness of the inoculation operation room environment is not affected.

- The inoculation operation area is mainly for the disinfection of plant materials, inoculation, transfer of medium, a succession of in vitro seedlings, preparation of protoplasts, and all technical procedures that require an aseptic operation, which is the most critical step in the research or production of the plant in vitro culture. It should meet the requirements of a dust-free level, and the air inlet is sequentially equipped with primary, medium, and high-efficiency three-stage filtration, which is in conjunction with the ultra-clean bench to achieve the aseptic operation of inoculation. The main pieces of equipment are an ultra-clean working table, an inoculation sterilizer, an ozone meter, and so on.

- The group culture area is mainly for light and dark cultures of plant materials to meet the environmental requirements in the differentiation cycle. The temperature range is 15-35℃, the humidity range is 40-70% RH, and the light intensity is 0-15,000 LuX. The main pieces of equipment are a temperature control system, cross-flow incubator, ozone meter, UV lamp, etc.

Figure 1. The layout of the transformation and tissue culture laboratory.

Figure 1. The layout of the transformation and tissue culture laboratory.

Common problems in tissue culture laboratories

- Contamination of materials due to condensation from the tissue culture process and the effect on light.

- Excessive energy consumption due to prolonged operation of air-conditioners and heat generated by conventional light sources.

- Traditional culture racks avoid the problem of condensation by placing them in compartments. The problem of low space utilization.

- Not designed according to the process flow, resulting in easy contamination of materials, operation inconvenience, and other issues.

- Temperature control failure can not be dealt with in time. Resulting in high indoor temperatures and extensive damage to materials.

Advantages

- Effective combination of our mature self-use experience and standard processes for greater practicality.

- Supporting technologies to solve the common problems mentioned above.

- Own a control system to reduce air-conditioning running time, and energy efficiency and increase equipment life.

- Professional design, providing complete platform building services.

- Highly recognized in the industry, allowing the establishment of a communication center at the front end of the technology.

- Timely response to after-sales service and the commitment to extend the warranty period.

- IoT remote monitoring and integrated control can be realized.

Please feel free to contact us to submit your requirements.

For research or industrial raw materials, not for personal medical use!

Figure 1. The layout of the transformation and tissue culture laboratory.

Figure 1. The layout of the transformation and tissue culture laboratory.