Curculin is a high-intensity sweetener. Like most proteins, curculin is heat sensitive, with reduced activity above 50℃. Because of its high sweetness and low caloric content, curculin has attracted interest in the food industry as a potential natural sweetener. However, the yield of curculin from fruits is limited, and the cost of extracting and purifying this protein is high. A potential solution to this problem is the development of microbial systems that can produce curculin.

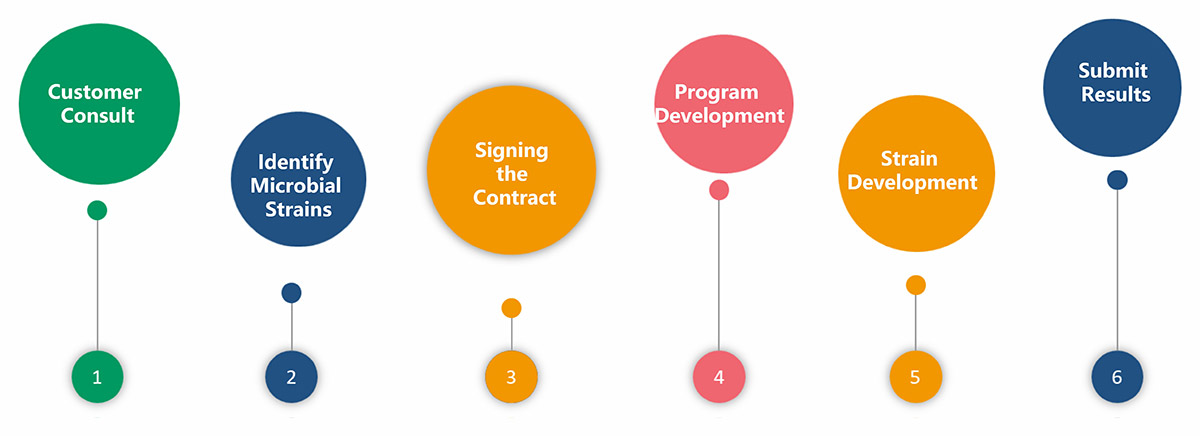

Lifeasible has a team of experienced experts, advanced genetic engineering technology, and a well-established quality system specializing in developing microbial strains for various applications. We pride ourselves on providing high-quality curculin production strain development services tailored to meet the specific needs of our clients.

Lifeasible provides comprehensive services for curculin production strain development, including strain characterization, scale-up production, custom services, and quality control. We will optimize the codon of the curculin gene to facilitate its expression in selected microbial strains. Documented quality and procedures of strain sources assessed are also available to ensure the stability of curculin-producing strains.

| Service Step | Service Content |

| Strain selection and screening | The first step in developing a curculin production strain is selecting and screening suitable microbial strains. Lifeasible has a large collection of microbial strains, including bacteria, yeast, and fungi, that can be screened for their ability to produce curculin. Our team can perform high-throughput screening assays to identify the best candidates for further development. |

| Expression vector construction and amplification | The next step is to amplify the curculin gene and clone it into a suitable vector to construct the expression vector. After success, the vector was amplified in E. coli DH5α. |

| Transformation and identification of strains | Under suitable conditions, the vector containing the curculin gene is transferred into the target strain by the plasmid transformation method and then identified by PCR and other techniques. |

| Strain optimization | Lifeasible offers a range of services to optimize the growth and production conditions of curculin-producing strains to achieve high curculin expression. |

| Strain characterization | After a curculin production strain has been developed and optimized, it is essential to fully characterize the strain to ensure its stability, safety, and efficacy. Lifeasible comprehensively characterizes the transformed strains by genetic stability analysis, proteomic analysis, and safety evaluation. The sweetness and taste-modulating activity of recombinant curculin will also be analyzed. |

Technical means: plasmid transformation

Microbial strains that can be developed:Bacillus subtilis, Escherichia coli BL21(DE3), Pichia pastoris, Saccharomyces cerevisiae, Aspergillus oryzae, etc.

Vectors: pAN7-1, pMOSBlue, pPICZB, etc.

Delivery results: microbial strains capable of expressing curculin, experimental data, pictures, and standard experimental reports.

Our expertise and experience in this field, combined with our commitment to providing customized and high-quality service, makes Lifeasible the ideal partner for all your curculin production needs. Please feel free to contact us if you need any assistance.

Reference

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Get Latest Lifeasible News and Updates Directly to Your Inbox

Adaptive Evolutionary Mechanism of Plants

February 28, 2025

Unraveling Cotton Development: Insights from Multi-Omics Studies

February 27, 2025