Biomethane is a green non-fossil source of energy and produced from biogas derived from organic matter (e.g. sewage, landfill, food waste or distillery waste) which makes it a renewable energy source. The production technologies of biomethane mainly are fermentation and gasification in modern bioenergy field. As an alternative energy source to fossil fuels, biomethane has a number of environmental benefits, the main one being that the production and consumption of biomethane derived from organic matter decomposition reduce the release of methane and other harmful gases into the atmosphere and the need for fossil fuels. Biomethane also allows the recovery of waste and the reduction of the use of chemical fertilizers, leading to a beneficial effect on the soil.

Biomethane can be used to inject into the natural gas grid as an efficient and flexible energy solution, allowing the use of energy from biogas in areas located far away from where the fossil energy is generated. More specifically, it can be applied to the important fields of heat generation, cogeneration heat/power, and natural gas vehicles. Final quality of biomethane depends on the operational parameters of the final use and on the upgrading technology used. In order to maximize efficiency in the process of usage, biomethane fuel is obliged to meet the specific standards and specifications around the world. For instance, the European specifications for natural gas and biomethane automotive market fuels were published in 2016/2017, including EN 16723-1 and EN 16723-2.

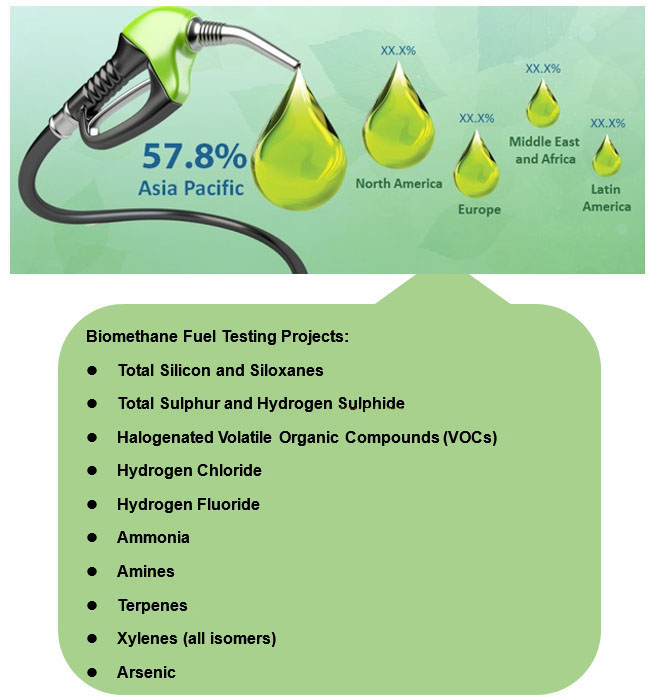

Figure 1. Quality testing of biomethane fuel

Figure 1. Quality testing of biomethane fuel

As a global leader in the field of biomethane fuel testing, Lifeasible has developed an advanced platform to provide professional services for the parameter measurement and comprehensive analysis of biomethane. The parameters affected the quality of biomethane fuel can be assessed at Lifeasible including but not limited to: total silicon and siloxanes, total sulphur and hydrogen sulphide, halogenated volatile organic compounds (VOCs), hydrogen chloride, hydrogen fluoride, ammonia, terpenes, amines, xylenes (all isomers), and arsenic.

Among the factors affected the usage of engine driven by biomethane fuel, siloxanes in biomethane take risk of abrasion and increase the probability for knocking. Hydrogen in biomethane has the risk of embrittlement for metallic materials, and water in biomethane may cause corrosion and driveability problems. Besides, in the presence of water, the corrosive of hydrogen sulfide could affect after-treatment devices, and combustion products could create problems by sticking the engine valves.

With amount of experience in the biomethane fuel testing field, we are able to provide you professional and tailored testing services according to your project requirements. Our experts always follow up on the development of technologies and regulations to continually improve our biomethane fuel testing capabilities. For more information, please feel free to contact us, we will be more than happy to help you.

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Get Latest Lifeasible News and Updates Directly to Your Inbox

Adaptive Evolutionary Mechanism of Plants

February 28, 2025

Unraveling Cotton Development: Insights from Multi-Omics Studies

February 27, 2025