A large number of biomass materials used in bioenergy production contain cellulose, hemicelluloses, and lignin, which are not conducive to the conversion of biomass materials to bioenergy. Therefore, biomass pretreatment is essential in the process of bioenergy production, and physical pretreatment is one kind of technique that is commonly used. Lifeasible provides technical support services related to physical pretreatment technologies, including technical consulting, project design and program optimization services. We guarantee high quality services that help customers solve technical problems in the physical pretreatment process.

As a common technique for pretreatment of biomass materials, physical pretreatment can not only be utilized alone, but also often combined with other pretreatment methods for the production process of bioenergy. Physical pretreatment can effectively reduce the size of the biomass material and increase its specific surface area, which is conducive to increasing the accessibility of enzymes and thus increasing the conversion rate of biomass materials and bioenergy yield. Physical pretreatment methods mainly include mechanical pretreatment and irradiation pretreatment.

Mechanical pretreatment

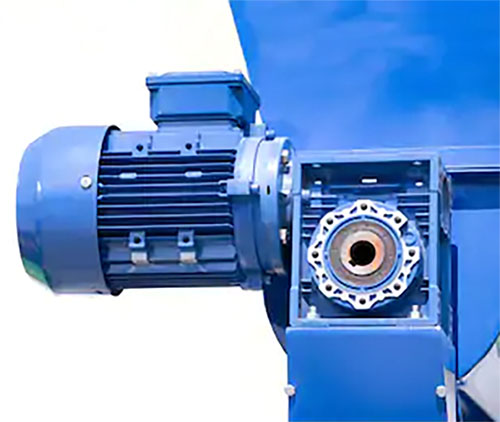

Mechanical pretreatment is a common pretreatment method for waste materials, including shredding, grinding, milling, and shock treatment. Mechanical pretreatment uses machinery to reduce the particle size of biomass materials, increase the specific surface area and pore size, and finally achieve the purpose of increasing the accessibility of enzymes and improving the conversion rate of biomass materials. Mechanical pretreatment can also decrease the crystallinity and polymerization degree of the raw materials, thereby further improving the digestibility of biomass.

Irradiation pretreatment

Irradiation pretreatment is another physical method used for the pretreatment of biomass materials. Irradiation pretreatment refers to the technologies to induce lignin degradation by using irradiations, such as gamma-ray irradiation, electron-beam irradiation, microwave, and ultrasound. Among them, gamma-ray irradiation is mostly used for liquid biofuel production, electron-beam irradiation is generally used for pretreatment before enzymatic saccharification, and microwave pretreatment is generally used in combination with mechanical pretreatment or chemical pretreatment. Irradiation pretreatment can effectively increase the degradability of biomass materials, thereby improving the conversion rate of biomass materials and the yield of bioenergy.

Different technologies are suitable for diverse biomass materials. Moreover, physical pretreatment process also involves a number of technical parameters that significantly affect the bioenergy production, such as initial particle size, feed rate, water content, machinery type, irradiation types, irradiation frequency, and exposure time. Therefore, in order to improve the conversion rate of biomass materials and the output of bioenergy, it is particularly important to optimize many of the parameters in physical pretreatment.

Lifeasible has solid expertise in physical pretreatment, and can provide personalized technical support services for customers based on biomass materials types and bioenergy production needs. We not only provide technical consulting and program optimization services, but also provide project design service for pretreatment process. Our services are dedicated to helping customers increase bioenergy yield and cost-effectiveness. If you have difficulty in the physical pretreatment process of biomass materials, Lifeasible is your reliable choice. Please feel free to contact us.

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Get Latest Lifeasible News and Updates Directly to Your Inbox

Adaptive Evolutionary Mechanism of Plants

February 28, 2025

Unraveling Cotton Development: Insights from Multi-Omics Studies

February 27, 2025