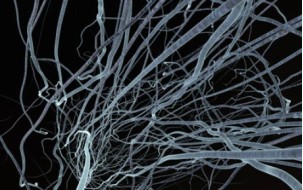

Nanofiber in a narrow sense refers to fibers with fiber diameter in the nanometer scale range (1-100 nm) and large length. In a broader sense, it also includes conventional fibers prepared by filling nanoparticles into fibers. Nanomaterials generally have the properties of surface effect, small size effect, quantum size effect, and macroscopic quantum tunneling effect. In contrast, nanofiber materials have these properties in addition to high porosity, large aspect ratio, large specific surface area, fine nanostructure, good biocompatibility, and natural reticular structure. There are various types of nanofibers.

Lifeasible can provide customers with material development, including cellulose nanofibers and bacterial cellulose. Cellulose nanofibers are new nanomaterials made from abundant and renewable sources of cellulose and have shown great potential for many applications due to their superior material properties. Bacterial cellulose is a polymer that can be synthesized under different conditions by certain microorganisms of the genera Bacillus acetate, Bacillus octococci, Rhizobium, and Bacillus soil.

For nanofiber product development, Lifeasible has dedicated scientific staff and expertise to carry out project development, production, testing, quality control, and mass production on a large scale, providing a complete integrated service for our customers. At the same time, we can also provide modification of nanofiber materials, modifying the original material from multiple aspects, improving its performance, and thus expanding the application of the product.

The following are our current product development solutions for nanofibers.

Lifeasible offers strong material development capabilities to provide product modification solutions for cellulose nanofibers. The modifications include acetylation of cellulose nanoparticles, sialylation, the addition of nanoparticles, the addition of coupling agents, etc.

Bacterial cellulose product development includes nano-carbon modification of bacterial fibers and other modification services for bacterial cellulose, which can improve the performance of bacterial cellulose in the corresponding fields and thus expand its application areas.

1. Electrostatic spinning technology

Electrostatic spinning technology is currently the most important basic method for preparing nanofibers. The core of this technology is to make the charged polymer solution or melt flow and deformation in an electrostatic field and then by the solute. The agent evaporates, or the melt cools and solidifies, after that a fibrous substance is obtained, a process referred to as electrospinning.

2. Composite spinning method

The compound spinning method produces ultrafine fibers to the extreme, and nanofibers can be obtained.

3. Molecular spinneret method

The molecular spinneret consists of a membrane containing a columnar organic molecular structure made up of disks, which are positioned in a designed position on the membrane. The disks are liquid crystal polymers, which have been developed in recent years from the synthetic chemistry of polymers. The polymer molecules are arranged into thin filaments in the disks within the membrane, and the fibers are released from the bottom of the membrane. The special design and positioning of the disks allow them to attract and stretch certain polymer molecules, and to cluster and orient the polymer molecules to obtain the desired structure of the fiber.

Lifeasible can provide product and technology development for our customers and customized product solutions, so please feel free to contact us if you are interested in our solutions.