Freeze structuring is also known as "Freeze alignment". In freeze structuring or freeze alignment, plant-based protein emulsions are frozen to form ice crystals. Removing heat from well-mixed slurry results in an isotropic structure of the ice crystals, but when heat is removed unidirectionally without mixing, the ice crystal alignment results in an anisotropic structure. The frozen products were subsequently dried without melting the ice crystals to obtain aligned and unique porous and interconnected fibrous microstructures. Their microfibrous structure resembles that of animal meat muscles, overlapping each other like layered sheets. The freeze structuring technique has been widely used for structuring meat, fish, and plant proteins.

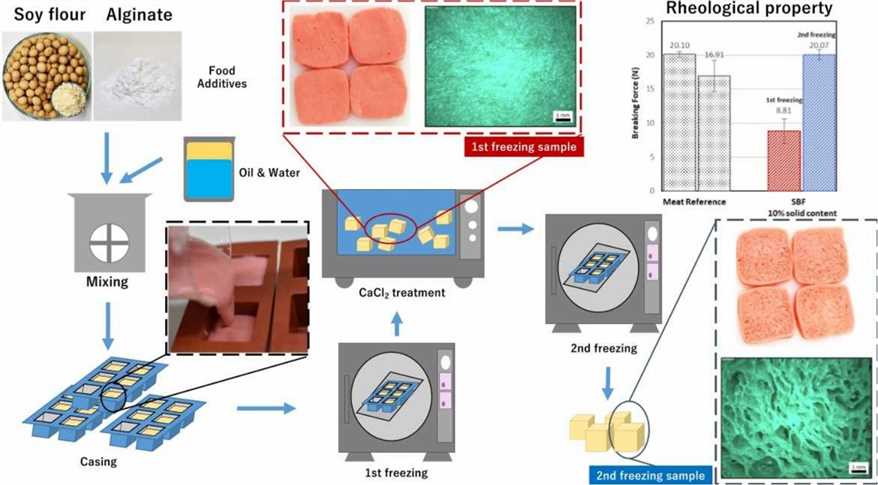

Fig.1. Preparation of soy protein-based food gels and control of fibrous structure and rheological property by freezing. (Chantanuson R, et al., 2022)

Fig.1. Preparation of soy protein-based food gels and control of fibrous structure and rheological property by freezing. (Chantanuson R, et al., 2022)

As more and more people continue to adopt vegan and vegetarian lifestyles, there is a growing need to understand and expand plant-based meat processing technologies. Lifeasible is committed to processing plant-based meats with similar structural and organoleptic properties to meat using plant-based protein freeze structuring technology. Our advanced freeze structuring technology platform is used to control the fibrous structure (i.e., anisotropic laminar porous structure) and rheological properties of soy protein food gels. The procedure of plant-based meat production based on freeze structuring technology is as follows:

(1) The dispersion of the plant-based protein solution is frozen to produce ice crystals arranged perpendicular to the cooling surface.

(2) Through the formation of ice crystals, parallel zones are formed, which surround the aligned plant-based protein molecules.

(3) During this process, the recipe ratio of moisture to protein content remains constant, producing a slender fibrous structure.

(4) The water is removed by freeze-drying to form a large block of hard fibrin.

(5) The gel network of fibrin can be rehydrated using an aqueous solution containing fats, stabilizers, pigments, and additives.

Lifeasible is a leading service provider of plant-based meats. We work closely with scientists and engineers in the fields of biotechnology and food science to expand the potential of freeze structuring technology for plant-based meat production. We aim to use freeze structuring technology to develop plant-based meat alternatives with unique textural characteristics. To meet consumer demand for plant-based meat texture, nutrition, and quality, Lifeasible offers customized solutions for texturized protein production based on freeze structuring.

The growth of ice crystals in protein gels is key to simulating the actual meat structure, and it is significantly influenced by the sample's gelling ability. We usually choose soybean powder with low gelling capacity.

Adjust the size of the ice crystals according to the freezing temperature and rate. To obtain different fiber products, proteins should have relatively good solubility before freezing, while during freezing, these proteins become insoluble.

The way each specific material reacts in the plant-based protein freeze structuring process requires us to be very innovative during the R&D phase to achieve each customer's individual goals. Lifeasible has conducted countless tests on various plant-based proteins and meat substitutes. We are ready to explore the value of freeze structuring technology to meet the growing demand for new, higher quality, and better tasting plant-based meats. Feel free to contact us for more information.

Reference