Fungal High-Density Solid State Fermentation Technical Services

With the continuous development of green agriculture and biotechnology, solid fermentation technology is gradually attracting attention from all walks of life. Compared with traditional liquid fermentation, solid fermentation utilizes a low-moisture environment and a solid substrate to provide an environment for microbial growth similar to that of fallen leaves or crop residues in nature. Fungal solid fermentation, by increasing culture density, achieves high yields and efficient conversion, allowing it to show great potential in biofertilizers such as microbial agents.

Lifeasible is an industry leader in agricultural research. Through systematic and precise research on the oxygen demand, pH, carbon source, nitrogen source, and micronutrient requirements of different fungi, we continue to design and develop innovative fermentation devices and processes to provide technical support and solutions for large-scale fermentation and production of high-quality fungal spores.

Application of Fungal High-Density Solid-State Fermentation Technology

- Bio-fertilizer and agricultural product processing. Through the fermentation process to improve the structure of organic matter, the production of bio-organic fertilizers and plant growth regulators, promote the development of the root system of crops, improve the nutrient absorption rate to help increase agricultural production and ecological balance.

- Functional food and health products. Develop fermentation products rich in polysaccharides, phenols, and other antioxidants to enhance food's nutritional value and health effects.

- Industrial enzyme production. Produce cellulase, protease, and other industrial enzymes to meet the needs of food processing, feed additives, and textiles.

Our Service for Fungal High-Density Solid-State Fermentation

Strain improvement and screening

High-quality strains adapted to high-density fermentation environments were bred through genetic modification and traditional screening techniques.

- Strain adaptation. We have strictly screened the commonly applied strains so that they have the characteristics of maintaining high metabolic activity and product generation ability in a high-density environment.

- Genetic Improvement and Directional Cultivation. We use advanced technology to optimize the tolerance, enzyme production capacity, or secondary metabolite synthesis level of strains so that they have a higher growth rate and transformation efficiency in high-density solid culture.

Matrix optimization and proportioning research

Various efficient fermentation substrates have been developed for different applications, and the raw material ratio and nutritional addition strategy have been optimized.

- Selection of substrate raw materials. Solid fermentation often use crop by-products, wood chips and other natural materials, these raw materials can provide a rich source of carbon and nitrogen for the fungus, and has good permeability.

- Moisture and nutrition regulation. We technically ensure balanced nutrition by precisely controlling the substrate's water content and adding the right amount of trace elements and vitamins to avoid affecting the expansion of the fungus due to insufficient moisture.

- Pretreatment and adjuvant addition. Physical and chemical pre-treatment of the substrate improves the efficiency of substrate utilization. Adjuvants are also added when necessary to further improve the pore structure and moisture distribution of the substrate.

Fermentation process control

With the help of modern sensors and automated equipment, key parameters such as temperature, humidity, and oxygen can be precisely controlled to improve the stability of the fermentation process and product quality. By optimizing parameters such as temperature, humidity, and aeration, we can shorten the fermentation cycle to 48-72 hours.

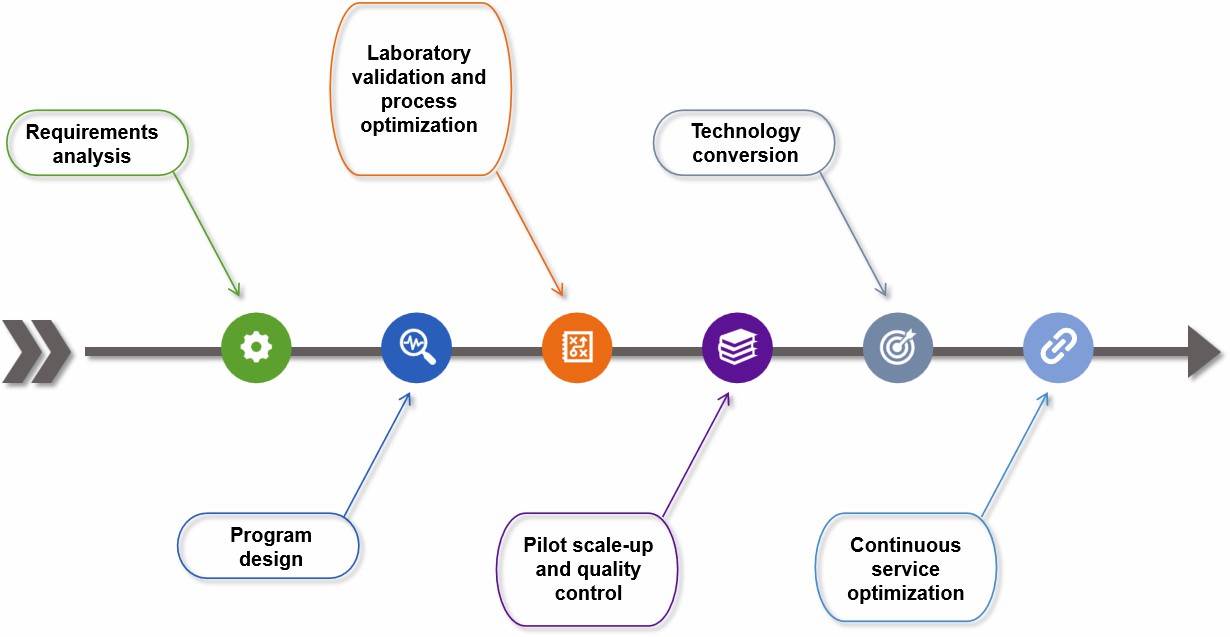

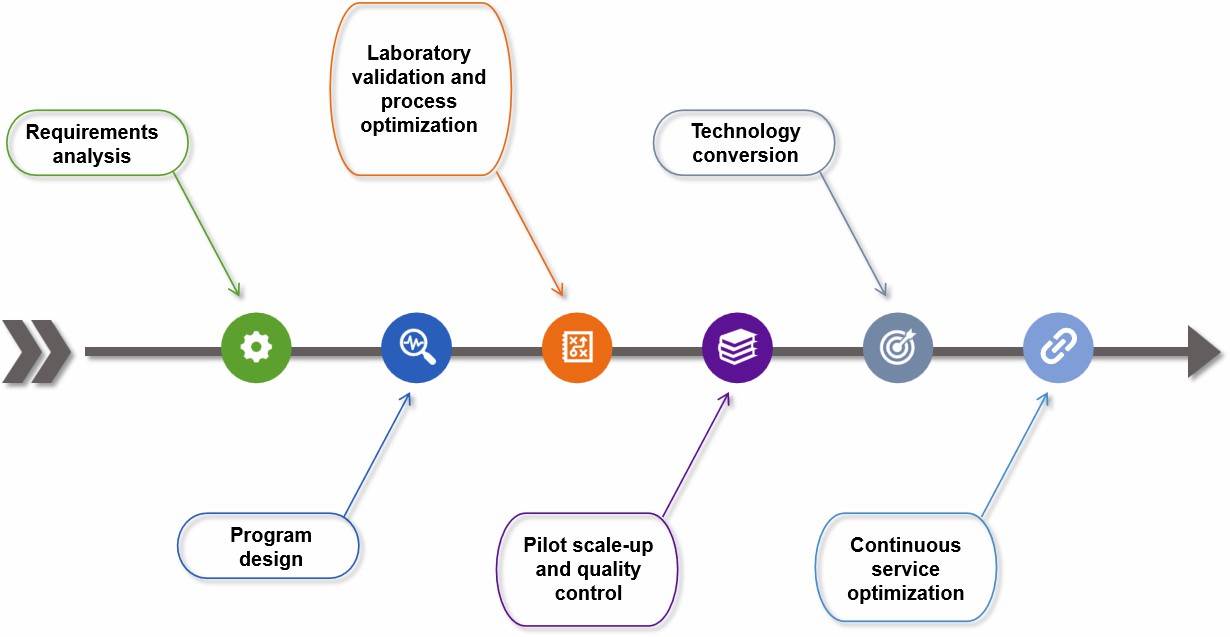

Our Process of Fungal High-Density Solid State Fermentation Technical Services

- Requirements analysis. Define target product functionality, cost, and compliance requirements.

- Program design. Provide strain, media, and process matching program.

- Laboratory validation and process optimization. In the laboratory pilot stage, conduct preliminary tests for different strains and substrates, and adjust the culture parameters according to the test data, gradually optimize the process to ensure the efficiency and stability of the technology.

- Pilot scale-up and quality control. Transfer the optimized process to the pilot plant for scale-up validation. Strict quality testing and data monitoring are implemented to ensure that the fermentation process is always in the best condition.

- Technology conversion. Provide full technical training to assist customers in completing the smooth transition from technology development to production application.

- Continuous service optimization. Regular visits, data analysis, and process improvement suggestions to help customers continuously improve production efficiency.

Fig.2 Our process of fungal high-density solid state fermentation. (Lifeasible)

Fig.2 Our process of fungal high-density solid state fermentation. (Lifeasible)

Highlights of Our Fungal High-Density Solid State Fermentation Technical Services

- High density and high efficiency. By optimizing multiple factors such as strains, substrates, and environmental parameters, we can significantly increase the generation rate and production efficiency of target products.

- Green and resource utilization. We utilize agricultural and forestry wastes as substrates, which not only reduces the cost of raw materials but also promotes the resourceful treatment of wastes, which aligns with the concept of sustainable development.

- Flexibility and customization. We can flexibly adjust our technical solutions according to different product requirements, including strain selection, substrate ratio, process parameters, etc. can be customized.

- Intelligent and controllable process. Our advanced automated monitoring system and data analysis platform make the fermentation process transparent and efficiently regulated, providing solid data support for continuous process optimization.

Fungal high-density ,solid-state fermentation is a comprehensive process that combines strain improvement, substrate optimization, environmental control, intelligent monitoring, and downstream processing, and Lifeasible is committed to providing customers with a green, efficient, and sustainable fermentation solution through continuous technological innovation and engineering practice. If you are interested, please feel free to contact us.

For research or industrial raw materials, not for personal medical use!

Fig.2 Our process of fungal high-density solid state fermentation. (Lifeasible)

Fig.2 Our process of fungal high-density solid state fermentation. (Lifeasible)