We use cookies to understand how you use our site and to improve the overall user experience. This includes personalizing content and advertising. Read our Privacy Policy

Monellin has a series of unique advantages such as safety, low calorie, no unnatural metabolites introduced into the body, maintenance of amino acid pool balance, and relatively simple cloning into microorganisms. It has the potential to be used as a food additive or drug. The sweetness of monellin is pH dependent, and the protein is odorless at pH < 2 and pH > 9. In the United States, monellin is classified as a food additive not generally recognized as safe (GRAS); however, in the European Union and Japan, monellin is considered a novel food additive that can be used in food after safety assessment, and regulatory approval.

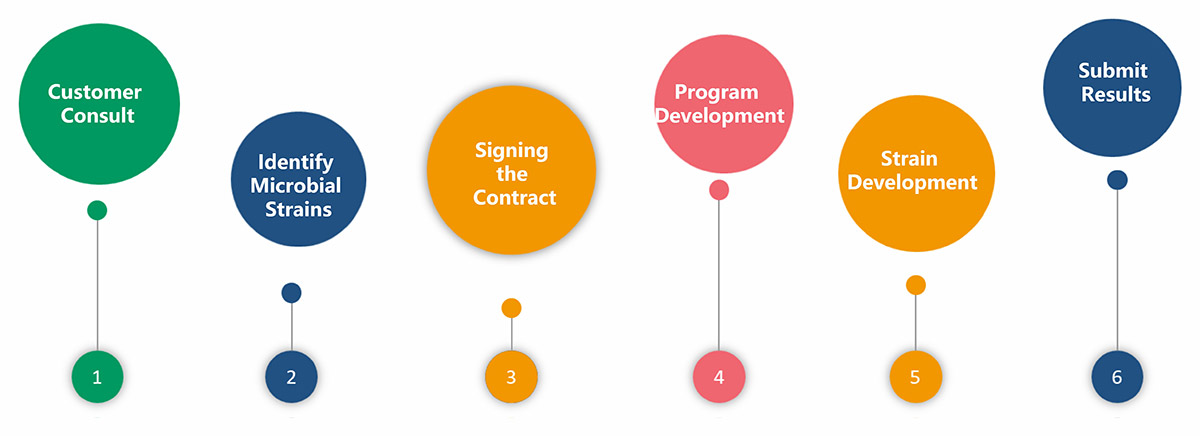

As one of the most promising sweet proteins, monellin has received extensive attention. However, extracting monellin from natural sources is costly, and the plants are difficult to cultivate. Therefore, scientists sought ways to express monellin in microorganisms. The increase in obesity and diabetes has also accelerated the demand for the industrial production of monellin. As a plant biological service CRO, Lifeasible provides monellin production strains development service to customers.

Expression of monellin in microbial systems is a feasible and efficient approach that can provide large and stable amounts of monellin whose sweetness and functional properties can be tuned as desired. At present, we have successfully developed monellin-expressing microbial systems for many customers. Different microbial expression systems have various advantages and disadvantages; we need to select and optimize according to the customer's target strains and application scenarios.

| Service Step | Service Content |

| Identify microbial strains to be developed | Determine the microbial strains to be developed, which can be sent by the customer or purchased by our company for you. |

| Preparation of strains, plasmids, and chemicals | Preparation of experimental materials such as Escherichia coli DH5α, vectors, restriction endonucleases, etc. |

| Culture medium | Select the medium and screening medium suitable for the growth of the target strain. |

| Construction of recombinant plasmids | First, the monellin gene is amplified and cloned into a plasmid according to the restriction site. Then the plasmid is transformed into E. coli DH5α for amplification. |

| Transformation, expression, and purification | The constructed plasmid is passed into the strain to be transformed. Subsequently, positive transformants will be selected by PCR technology to expand the culture. |

| Expression, purification, and analysis of recombinant monellin | The monellin expressed by the microbial system is collected and purified in the culture medium and then analyzed for sweet threshold and thermostability. |

Technical means: plasmid transformation

Microbial strains that can be developed: Saccharomyces cerevisiae,food yeast Candida utilis, Pichia pastoris, Escherichia coli, Bacillus subtilis, etc.

Vectors: pCU1 plasmid, pETDUET plasmid, pHPMS plasmid, etc.

Delivery results: microbial strains capable of expressing monellin, experimental data, pictures, and standard experimental reports.

Lifeasible, as a professional biotechnology company, is oriented to the needs of our customers and develops solutions that meet all their needs. We will do our best to provide our customers with scientific, accurate, and realistic experimental results. If you need to develop a microbial strain for monellin production, please feel free to contact us.

References

Get Latest Lifeasible News and Updates Directly to Your Inbox

Mechanisms Regulating Plant Chloroplast Biogenesis

April 15, 2025

We use cookies to understand how you use our site and to improve the overall user experience. This includes personalizing content and advertising. Read our Privacy Policy