Pentadin has a molecular mass of 12,000 Da and is relatively stable due to intramolecular disulfide bonds between its subunits. With its pure sweetness, pentadin has received a lot of attention. Studies on pentadin have largely focused on its potential as a natural sweetener and its effect on blood sugar levels. The source of pentadin is limited, and the way of extracting it from natural plants limits its research and application. Scientists have been developing microbial systems to express pentadin more and more with the development of biotechnology.

Lifeasible has extensive experience and significant advantages in developing recombinant protein production strains. Our team of experienced scientists has a deep understanding of sweet proteins. Using advanced technology and equipment, we develop customized pentadin production strains.

We provide our customers with high-quality pentadin production strains designed to meet their unique needs. A wide range of services related to the development of pentadin production strains can be provided by our highly qualified team of experts with extensive experience in microbial fermentation.

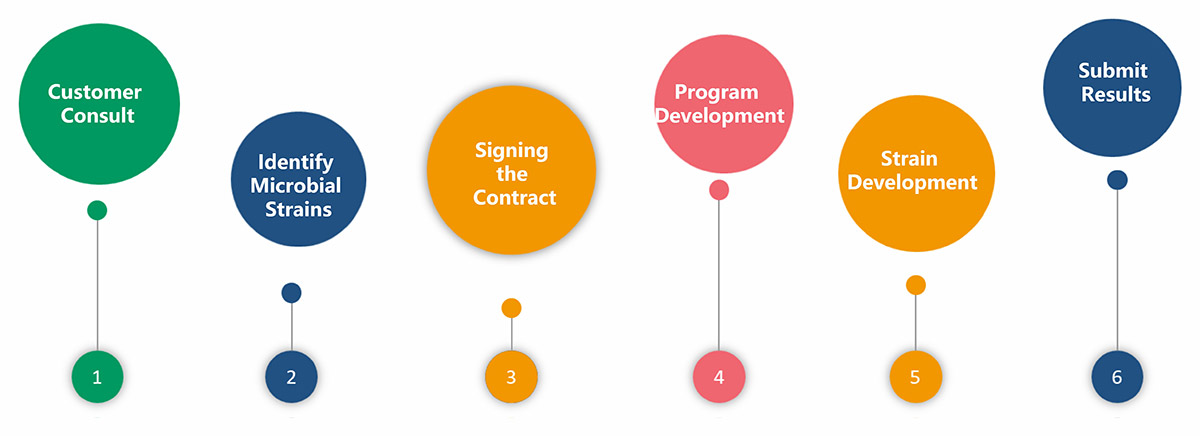

| Service Step | Service Content |

| Strain identification and authentication | The first step in pentadin production strain development is the identification and authentication of suitable microbial hosts. We offer various services to identify and authenticate bacterial, fungal, and yeast strains. This includes 16S rRNA sequencing, fungal internal transcribed spacer (ITS) sequencing, and whole-genome sequencing. These services can help to ensure the genetic stability and purity of the selected strains. |

| Expression vector construction and amplification | In the next step, the pentadin gene will be cloned into a suitable vector, and the resulting vector will be transformed into E. coli DH5α for amplification and recovery. |

| Strain Transformation | The recombinant expression plasmid will be transformed into the determined strain, and the successfully transformed clones will be screened through the selection medium. |

| Strain optimization | After strain identification, the next step is to optimize the expression level of the pentadin. We offer various services to optimize pentadin expression levels, including vector construction, gene editing, and gene knock-in. |

| Strain characterization | The final step in pentadin production strain development is the characterization of the selected strains. This includes evaluating various biochemical and physiological properties, such as growth rate, nutrient utilization, and metabolic profile. |

Technical means: plasmid transformation

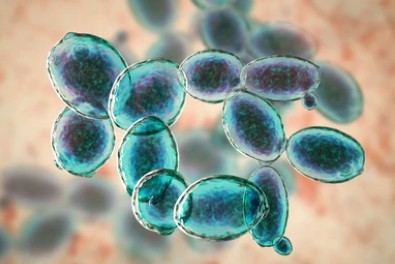

Microbial strains that can be developed: Pichia pastoris, Saccharomyces cerevisiae, Aspergillus oryzae, etc.

Vectors: pCU1, pETDUET, pAN7-1, etc.

Delivery results: microbial strains capable of expressing pentadin, experimental data, pictures, and standard experimental reports.

Lifeasible provides comprehensive pentadin production strain development services to help our customers develop strains for efficient pentadin production. Our experienced team of experts uses advanced genetic engineering techniques, a well-established quality system, and efficient upstream and downstream process development to optimize pentadin production. We are your ideal partner, so please contact us directly for your needs.

Reference

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Get Latest Lifeasible News and Updates Directly to Your Inbox

Adaptive Evolutionary Mechanism of Plants

February 28, 2025

Unraveling Cotton Development: Insights from Multi-Omics Studies

February 27, 2025