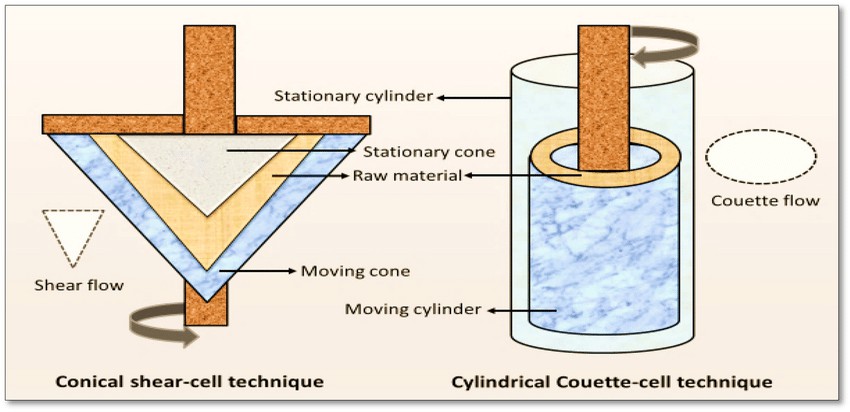

Shear cell technology is a new technique for fabricating artificial meat based on the concept of flow-induced structures. The process can be performed in a conical shear cell or a cylindrical Couette cell, using well-defined flow fields to build up the biopolymer material. This process has advantages over extrusion because the deformation inside the device is well-defined and constant during the process. The combination of simple shear and heating forms a fibrous structure that is stable on cooling and does not deform afterward. To extend this concept of shear-induced structures, the Couette cell device was proposed. This device successfully prepared meat analogs at high temperatures without losing structural consistency, as usually seen in extrusion processes. In addition, the design of the Couette cell facilitates the productivity of meat analogs by simply increasing the size and length of the cylinder, and even the thickness of the product, increasing the capacity of the device.

Fig.1. Conical shear cell technique and cylindrical Couette cell techniqe. (Singh M, et al., 2021)

Fig.1. Conical shear cell technique and cylindrical Couette cell techniqe. (Singh M, et al., 2021)

As more and more people continue to adopt vegan and vegetarian lifestyles, there is a growing need to understand and expand plant-based meat processing technologies. Lifeasible is committed to processing plant-based meats using plant-based protein shear cell technology to blend plant-based protein ingredients with water through shear flow. Our advanced shear cell technology platform transforms plant-based protein into a layered fiber structure that closely matches the appearance and texture of the meat, whether it is soy, wheat, pea, canola, or corn.

Lifeasible is a leading service provider of shear cell technology for building plant-based proteins and has experience developing commercial applications of this technology. We work closely with scientists and engineers in biotechnology, biopharmaceutical, and food science to expand the potential of this technology for plant-based meat manufacturing. Our goal is to make this technology available to industry, chefs, and consumers in home cooking. To meet consumer demand for plant-based meat texture, nutrition, and quality, Lifeasible offers customized solutions for texturized protein production based on shear cell technology.

Factors such as processing time, temperature, and shear rate can alter the shear-induced structure. We control processing time by regulating the barrel speed and temperature of the equipment, as well as processing plant proteins into homogeneous, layered, and multilayered fibrous structures with the help of anisotropic histones and a simple combination of shear force and heat.

The way each specific material reacts in the plant-based protein shear cell process requires us to be very innovative during the R&D phase to achieve each customer's individual goals. With an in-house laboratory equipped with a conical shear cell, Lifeasible has conducted countless tests on various plant-based proteins and meat substitutes. We are ready to explore the value of shear cell technology to meet the growing demand for new, higher quality, and better tasting plant-based meats. Feel free to contact us for more information.

Reference

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Get Latest Lifeasible News and Updates Directly to Your Inbox

Adaptive Evolutionary Mechanism of Plants

February 28, 2025

Unraveling Cotton Development: Insights from Multi-Omics Studies

February 27, 2025