Spider silk has unique strength and ductility. It is so tough that it dwarfs all man-made rubbers and fibers. In addition to its excellent mechanical properties, another reason why researchers favor spider silk is that its main component is biological protein, which makes it very biocompatible. The domestic silkworm, which synthesizes many proteins, can also spit silk cocoons, and can be reared on a large scale, making it a more developed type of bioreactor. Both spider and silk proteins are composed of tandem repeats, rich in Gly and Ala; the gene sequences and structures are also similar, composed of many repeats and rich in high GC.

Lifeasible's staff will provide you with product development services for spider silk, from preparation steps to spider silk performance testing; we have extensive experience in providing you with solutions.

Spider silk proteins contain both crystalline and amorphous structures, the former adding to the physical strength of the silk and the latter adding to its ductility. At the same time, some of the intrinsic structures have certain orientation relationships with spider silk, and these orientation relationships also, to some extent, enable spider silk to have excellent ductility properties. In addition, the researchers found that the rate of spider silk spitting may change the microscopic orientation of the molecules to some extent, which may affect the mechanical properties of the spider silk. These complex protein molecules and their intrinsic microscopic orientation relationships make it difficult to synthesize fibers with comparable properties chemically. In the case of spiders, transgenic technology has allowed the common house silkworm to secrete silk with the same protein composition as spider silk, thus greatly increasing the yield of spider silk. This method involves injecting spider genes into very small eggs by electroporation, thereby enabling the cultivated silkworms to secrete silk containing spider silk genes.

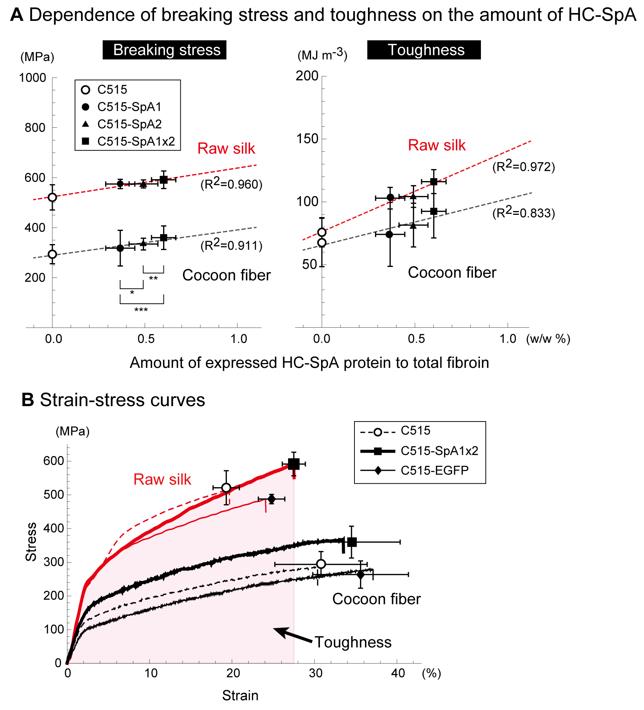

Fig.1 Fracture stress and strain-stress curves of spider silk spit by silkworms. (Kuwana et al., 2014)

Fig.1 Fracture stress and strain-stress curves of spider silk spit by silkworms. (Kuwana et al., 2014)

There are currently two distinctly different methods for introducing exogenous genes into the genes of the house silkworm: the first is achieved by using a baculovirus as a vector, which is usually less efficient; the second is achieved by using piggyBac as a vector, which is about 10 times more efficient at transgenesis than the former.

Obtain a cDNA library of the silk gland of the spider. Poly(A)+ RNA was extracted from silk glands, cDNA was synthesized using primers, and a cDNA library was created using a targeted cloning method.

Generate modified silk heart protein H-chain constructs.

Silkworm eggs are acid-treated for 30 minutes and 3 hours after spawning. The plasmid DNA is injected into the eggs 6 to 10 hours after the egg laying along with the helper plasmid. The hatched larvae are reared and allowed to mate with each other. Six to seven days after egg laying, the resulting embryos are screened for the presence of transgenic individuals using fluorescence microscopy. Silk obtained from the next generation is used for protein analysis and tensile testing.

To roll a silk fiber from a cocoon, each cocoon was first boiled in deionized water for 1 minute. The cooked cocoons were then soaked in cold water for 1 minute.

The silk glue layer swells during this process, which helps to roll the fiber out of the cocoon.

Single-fiber mechanical tests are performed using load cells. Toughness values are calculated from the stress-strain curve by combining them with mathematical software.

If you are interested in our services, please feel free to contact us, and we will provide you with a customized solution.

Reference

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Get Latest Lifeasible News and Updates Directly to Your Inbox

Adaptive Evolutionary Mechanism of Plants

February 28, 2025

Unraveling Cotton Development: Insights from Multi-Omics Studies

February 27, 2025