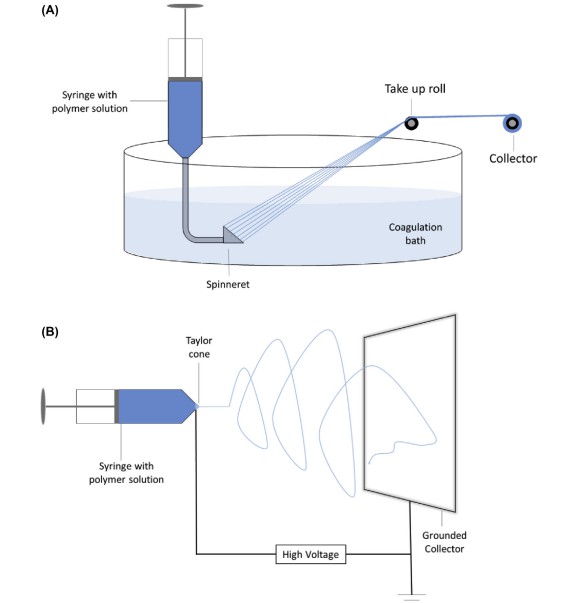

Spinning methods are considered a bottom-up strategy for the organization of plant-based proteins. Fiber spinning techniques apply an external force to the polymer solution ejected from the needle or spinneret and then collect the elongated polymer into solid fibers. The applied external force, other environmental conditions, and inherent polymer properties control the final properties of the resulting fibers. Common types of spinning technologies available today include wet, electrostatic, jet, and blow spinning. Wet spinning simply extrudes a polymer solution through a spinneret and into a non-solvent, allowing the polymer to precipitate into fibers. Electrostatic spinning methods extrude the polymer solution through a needle with an electrical potential, and the charge repulsion eventually causes the polymer to form fine fibers. Jet spinning and blow spinning are techniques that use high-speed rotation and high-pressure gas to force the polymer into a fiber structure, respectively.

Fig.1. Wet spinning (A) and Electrospinning (B) processes for the production of fifibrils. (Kyriakopoulou K, et al., 2019)

Fig.1. Wet spinning (A) and Electrospinning (B) processes for the production of fifibrils. (Kyriakopoulou K, et al., 2019)

As more and more people continue to adopt vegan and vegetarian lifestyles, there is a growing need to understand and expand plant-based meat processing technologies. Lifeasible is committed to using spinning technology to create high-quality vegetable protein fiber bundles to produce mock meats. Our team of experts develops food-grade conditions suitable for plant-based protein spinning to promote their scalability and application in food science, aiming to mimic the texture of meat for consumers on plant-based diets. We are well-established in testing both of the following technologies:

Lifeasible is a leading provider of plant-based meat services that spins plant-based protein fibers to mimic the texture of meat, including hand-rolled pork and steak. To meet consumer demand for plant-based meat texture, nutrition, and quality, Lifeasible offers custom solutions for spinning-based textured protein production.

Our scientists improve experimental conditions for spinning plant-based proteins in several ways, including optimizing solution type, viscosity, conductivity (for electrostatic spinning), and surface tension. In addition, we optimize the process parameters for each technique, such as adjusting the voltage, flow rate, and distance between the jet needle and fiber collector in the case of electrostatic spinning.

The spinnability of proteins depends on their solubility (many proteins require harsh non-food grade solvents to dissolve) and protein conformation (randomly curled structures are best suited for spinning due to their flexibility). We usually select specific proteins, especially maize alcohol-soluble proteins and gelatin, which have better spinning than other proteins. In addition, we combine proteins that are not easy to spin with proteins that are easier to spin to improve spinning efficiency. We continue developing more plant proteins and their combinations for optimal spinning conditions.

Spinning technology forms fine fiber bundles of polymers and has great potential to do the same for food-grade proteins. Lifeasible has advanced spinning methods to create plant-based protein fiber bundles that help plant-based meats achieve the same sensory profile as traditional meats by improving product texture, mouthfeel, and appearance. Our team continues to improve plant-based protein fiber spinning to make it more efficient, commercially scalable, and affordable. Feel free to contact us for more information.

Reference

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Get Latest Lifeasible News and Updates Directly to Your Inbox

Adaptive Evolutionary Mechanism of Plants

February 28, 2025

Unraveling Cotton Development: Insights from Multi-Omics Studies

February 27, 2025