Isolation and Purification of Herbal Components

Inquiry

The herbal extracts or extracts obtained by the general extraction method are still mixtures and are large, low in active ingredients, and full of impurities, so they need to be further removed and separated, and purified. Separation and purification is the process of separating the herbal extract from the residue, sediment, and solid impurities, and then using an advanced and rational separation and purification process to remove the invalid components and retain the active and auxiliary components. Lifeasible offers services for the separation and purification of herbal medicines to reduce the volume, increase the content of active ingredients, and improve the stability of the medicine. We cover a wide range of sample states (fixed, liquid) and ecological processing of herbal residues, allowing you to save effort and energy from raw material preparation to recycling.

We can provide you with the preparation and calibration of herbal chemical controls for determining the authenticity of herbal medicines and evaluating the quality of medications, helping you to improve the quality control of herbal and ensure the safety and efficacy of medicines.

We offer a wide range of techniques for the identification, preparation, and structural analysis of natural products, herbal active ingredients, and trace impurities in pharmaceuticals. We offer a full range of services from separation and purification to structure elucidation, structure confirmation, and impurity-specific test method development and validation.

We will assist you in selecting the appropriate analytical method to identify and determine the content of impurities accurately and to determine the reasonable limits of impurities in the context of pharmacology and toxicology, as well as structural identification and analysis.

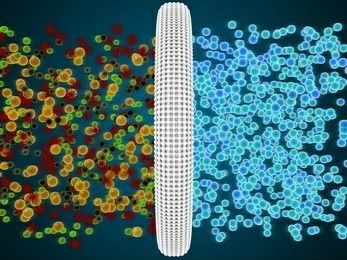

We offer a variety of methods, including microporous resin adsorption, supercritical fluid extraction, ultrafiltration technology, and microfiltration membranes for herbal purification. This allows us to achieve a good separation of the active and inactive components in the herbal production process so that the active components are retained, and the inactive components are removed to meet the quality requirements.

We have introduced chromatographic purification technology with the high mechanical strength of the stationary phase, high regeneration capacity, and efficient and precise removal of impurities, macromolecules, and colloidal particles, which can help you to prepare high-quality herbal liquid formulations.

We consider the fact that herbs are solid products and that their desulfurization techniques are unique, so we consider the impact of the various factors of the desulfurization process on the product and use the most appropriate method for each sample to ensure that the quality of the product is not affected.

The main objective of the ecological model we have established for the comprehensive utilization of herbal medicine residues is to achieve the comprehensive, efficient, and circular utilization of herbal medicine resources. We are committed to establishing a resource recycling pathway between the herbal plant, the herbal factory, and the residue treatment.

Different methods have different characteristics, and therefore Lifeasible uses various methods in the separation and purification of herbs depending on the formulation, composition, chemical properties, and the dosage form required for the preparation. Please feel free to contact us to compare different isolation and purification methods to facilitate herbal research.

For research or industrial raw materials, not for personal medical use!

Related Services